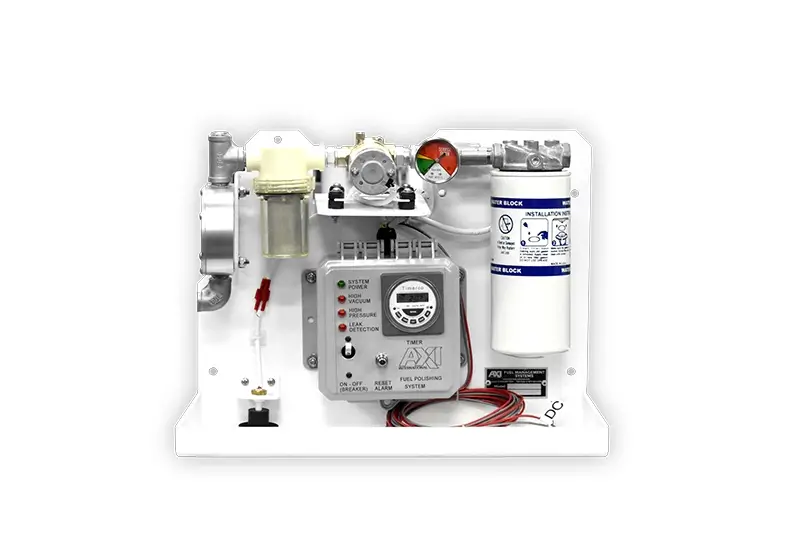

FPS LX-F

- Automatically removes contaminants from fuel storage tanks through user-scheduled filtration (10 GPM flow rate)

- Notifies users of routine maintenance or system faults such as needed filters changes or flow restrictions

- Compact design for tight indoor installations

- Drip tray with built-in leak detection

- Field connections for external integrations such as remote monitoring and system shutdown capabilities

- Robust set of available upgrade options

Description

The FPS LX-F is a programmable, fully automated, fuel maintenance system that removes water, sludge, and other contaminants from fuel storage tanks through routine filtration. The system’s compact design allows for tight indoor installations such as inside gen-set enclosures or engine rooms. With a 10 GPM flow rate, the FPS LX-F can polish up to 4,800 gallons (18,168 liters) of fuel in a runtime of 8-hours. Robust system upgrade options are available for this system and are outlined below.

Click here to download the complete technical sheet

System features:

Automated Filtration

Establish a fuel polishing runtime schedule with up to three start and stop times for each day of the week

Smart System Alarms

Automatic system shutdown with notifications of needed maintenance or system faults

Remote Monitoring

Available system integration with external monitoring systems for observation of system statuses

Touchscreen Controller

(Only available when paired with a TSC controller. Controller upgrade may also be required for certain option combinations.)

Modify runtime schedules and system settings with an intuitive user interface

System options:

Manual Additive Injection

Manually draw additive into the polisher with a dedicated supply port and ball valve

Auto Water Drain (AWD)

Automatically drain water separator of collected water for decreased frequency of maintenance

Pressure Transmitter

Replace standard pressure switch for detailed monitoring of pressure levels in the system

Flow Transmitter

Replace standard flow switch for detailed monitoring of flow rate in the system

Multi-Tank Polishing/Transfer

Polish and transfer fuel between multiple fuel storage tanks

Multi-Point Flow Path

(Only available when paired with a TSC controller. Controller upgrade may also be required for certain option combinations.)

Add multiple supply and return valves for better tank cleaning coverage

Fuel Heater

Warm up circulated fuel to resist gelling in freezing temperatures

Additional information

| Brand | AXI International |

|---|---|

| Nominal Flow Rate | 10 GPM/600 GPH (38 LPM/2271,3 LPH) |

| Primary Filter | *Standard filter element, unless otherwise requested. |

| Filtro Secondario | 3, 10 or 25μ Fine Filter or 3, 10μ Water Block |

| Fuel Conditioner | LG-X 3000 Inline Magnetic Conditioner |

| Pump | 3/4 HP Spur Gear Pump |

| System Controller | Smart Filtration Controller with Safety and Alarm Features |

| Power | 120V/60Hz/1Ph or 230V/50Hz/1Ph |

| Plumbing | Stainless Steel |

| Ports | 1” Equivalent JIC 37° Flare In, |

| Construction | Powder Coated Aluminum Back Plate |

| Dimensions | ≈ 26” x 34” x 12” (A x L x P) |

| Weight | ≈ 125 lbs (57 kg) |

| ATTENTION | Do not use with fluids with a flash point below 100°F (37.8°C). |